Whether in new builds or renovations, insulating unused attic space by blowing in loose-fill insulation is a quick and easy way to achieve effective insulation in both winter and summer. This technique is covered by DTU 45.11 and is effective for homeowners, as well as being cost-effective for professionals. Here is our comprehensive guide to everything you need to know about blown-in attic insulation!

Blown attic insulation: what are the advantages?

What are the advantages ofblown insulation for attics? The first advantage is more relevant to renovation projects, since the roof is responsible for around 30% of a home's energy loss. It is therefore often the first step taken to achieve energy savings.

Secondly, blown-in attic insulation stands out for its ease of installation: loose-fill insulation does not require cutting and does not generate product waste. Installation takes only a few hours to insulate an area of 100m².

Third advantage: the loose form of the insulation fills even the smallest gaps, thereby limiting thermal bridges. In contrast, insulation of unused attic space with rolls or panels can be discontinuous depending on the substrate: beams, corners, cracks, etc.

Finally, depending on the insulation chosen, the performance of blown attic insulation is increased tenfold. For example, bio-based insulation such as cellulose insulation wood fiber will help regulate humidity levels thanks to its hygroscopic properties. This type of insulation also provides real comfort in summer, when the temperature in attics can rise to 60°C.

Blown attic insulation: what are the disadvantages?

The main point to bear in mind when insulating attics using blown insulation is compliance with standard DTU 45.11. This regulation describes each step to be followed when insulating unused attic space using loose-fill insulation (mineral wool or cellulose insulation). Strict compliance with this standard guarantees building owners and users safe, compliant, and durable insulation.

Blowing insulation into attic spaces, unlike blowing it into walls, means that the insulation is sprayed onto a loose surface rather than into a closed cavity. The loose insulation (whatever type it is) will then settle in the hours following its installation. This is known as settling. This settling is known and measured during the certification of loose-fill insulation by ACERMI, and is therefore taken into account during installation. The installer blows in a thickness of insulation greater than the thickness after settling. It is the thickness after settling that certifies the defined thermal resistance.

For example, with cellulose insulation , 280 mm of insulation is required after settling to achieve a thermal resistanceof R=7m2.K/W. The installer will therefore blow in 355 mm during application (corresponding to the % of settling certified in ACERMI certificate No. 12/D/157/784).

Blown-in attic insulation: which insulation material should you choose?

To achieve effective attic insulation using blown insulation, it is important to choose a high-performance thermal insulator. The most common types are mineral wool (which looks like white flakes) and cellulose insulation for a more eco-friendly choice (gray flakes). However, other bio-based materials can also be blown into unused attic spaces, such as recycled cotton or wood fiber.

The advantage of choosing a bio-based insulation material, such as cellulose insulation, is the comfort it provides in summer, when outdoor temperatures are at their highest. French roofs are generally covered with tiles or slates. These materials are the only ones that block heat before it enters the attic. As they are dense but not very thick, heat can easily penetrate them, and it is not uncommon for the temperature in attics to rise to extreme levels. The only remaining barrier to slow down the entry of this heat into the building is the insulation in the attic space.

Choosing a thermal insulation material that performs well in terms of summer comfort helps maintain a stable indoor temperature for longer, avoiding the need for air conditioning. Thanks to its high phase shift capacity, cellulose insulation the entry of heat into the house by up to 9.5 hours.

Blown insulation for attics: how to do it?

As previously indicated, the insulation of unused attic space by blowing in loose-fill insulation is covered by NF DTU 45.11. Available from AFNOR, this document outlines all the steps to follow to ensure that the insulation of unused attic space by blowing in loose-fill insulation is compliant and durable:

Step 1: Protective equipment

Wear appropriate personal protective equipment, including a P2 dust mask. Safety glasses, coveralls, gloves, and safety shoes are not mandatory but are strongly recommended.

Step 2: Inspection of the attic space

Before blowing insulation into the attic, it is essential to carry out a preliminary inspection to recognize and identify any areas requiring special attention:

– continuous support that can withstand the weight of the insulation,

– ventilated attic,

– installation of deflectors around the perimeter if necessary,

– identification of recessed spotlights and flues,

– absence of moisture,

– condition of the electrical installation,

– condition of the old insulation (cover the kraft paper if it is positioned on the attic side).

Step 3: Safety distance around flues

Before blowing in the insulation, a barrier must be installed around all flues, whether in use or not. The barrier consists of rigid panels (metal, wood, plaster, or rigid A2-s1, d0 insulation panels) and must be installed at a minimum safe distance of 10 cm from the flue. Its height is equal to the height of the blown insulation, plus 10 cm. This safety volume must remain empty so as not to create a heat trap.

Step 4: Handling electrical devices

Ensure that the ventilation unit is located outside the area intended to receive the blown insulation. If this is not the case, it must be suspended from the roof structure. Check that the electrical cables are sheathed. Also place the junction boxes outside the insulation: if this is not possible, mark them with appropriate signage and check that they are in good condition.

Step 5: Protecting recessed lighting

Recessed spotlights, whether halogen or LED, must be protected. Install dustproof covers that comply with DTU 45.11 on each spotlight. Plastic flower pots or domes are prohibited. Hang the associated transformers from the frame. If the cable is too short, protect it with a cover identical to the one used for the spotlight. It is recommended that the covers be glued in place.

Step 6: Treatment of access hatches

The access hatch must be surrounded by a rigid stop that is at least 5 cm higher than the thickness of the blown insulation. Insulate the hatch with a panel whose thermal resistance is at least equal to that of the blown insulation.

Step 7: Marking the height of the insulation

Install graduated gauges in the attic to measure the height of the blown insulation. There must be at least 4 gauges per100m² and their graduations must be visible from the access hatch to facilitate checks.

Step 8: Blowing in loose-fill insulation

Once these preliminary steps have been completed, you can start blowing in the insulation, starting with the furthest parts and gradually working your way back towards the access point. Make sure you distribute the insulation evenly over the entire surface to be insulated. Ensure that the insulation does not come into contact with the roofing material and leave the safety voids empty.

Step 9: Site sheet

Once the insulation has been blown into the attic, a site report must be completed in triplicate. Thefirst copy must be stapled in the attic with three labels from the blown insulation bags, thesecond copy must be kept by the owner, and thethird copy must be kept by the installation company.

Step 10: Label on the electrical panel

It is important to inform subsequent contractors of the rules to be followed in attics insulated with blown insulation. For this reason, an information label should be affixed to or near the building's electrical panel.

Examples of these documents are available in our "DOWNLOADS" section >>

Blown-in attic insulation: how thick should it be?

The thickness of insulation required for insulating unused attic space varies from one material to another, depending on its thermal conductivity, density, and the desired thermal resistance. These factors (including the thickness to be blown in) are indicated in the material's ACERMI certificate (available here or from the manufacturer).

In renovation projects, the "standard" thermal resistance is R =7m2.K/W.

In RE2020 construction, insulation in unused attic space tends to achieve a thermal resistance of R =10m2.K/W.

For example, for cellulose insulation , which has a thermal conductivity certified by ACERMI of 0.040 W/(m.K), 355 mm of insulation (which will settle to 280 mm) must be blown in to achieve a thermal resistance of R =7m2.K/W.

To achieve an R value of10m2.K/W, 505mm of insulation must be blown in (which will settle to 400mm).

Blown attic insulation: how much does it cost?

The price of blown-in attic insulation depends on several factors: the surface area to be insulated, the presence or absence of specific points and their quantity, the choice of insulation material, etc.

Today, there is little difference in cost, for the same surface area, between mineral wool and cellulose insulation. Cotton or wood fiber insulation may be slightly more expensive.

Find an applicator

Would you like to find out where your nearest Igloo France Cellulose applicator is located?

Request a quote

Are you a professional and want to know the price of cellulose insulation France cellulose insulation ?

Blown attic insulation: how long does it last?

Blown attic insulation has a lifespan of around 20 years when installed using mineral insulation such as glass wool or rock wool.

With a bio-based insulation such as cellulose insulation, blown attic insulation is much more durable (lasting around 50 years).

Blown-in attic insulation: should the old insulation be removed?

DTU 45.11 does not require the removal of old insulation when renovating the thermal insulation of unused attic space. However, it is generally recommended, particularly in cases where the old insulation is in poor condition, if it already covers previous insulation (risk of excessive weight on the ceiling), or if it is wet. In all cases, removing the old insulation before installing new insulation allows you to take full advantage of the performance of the new material.

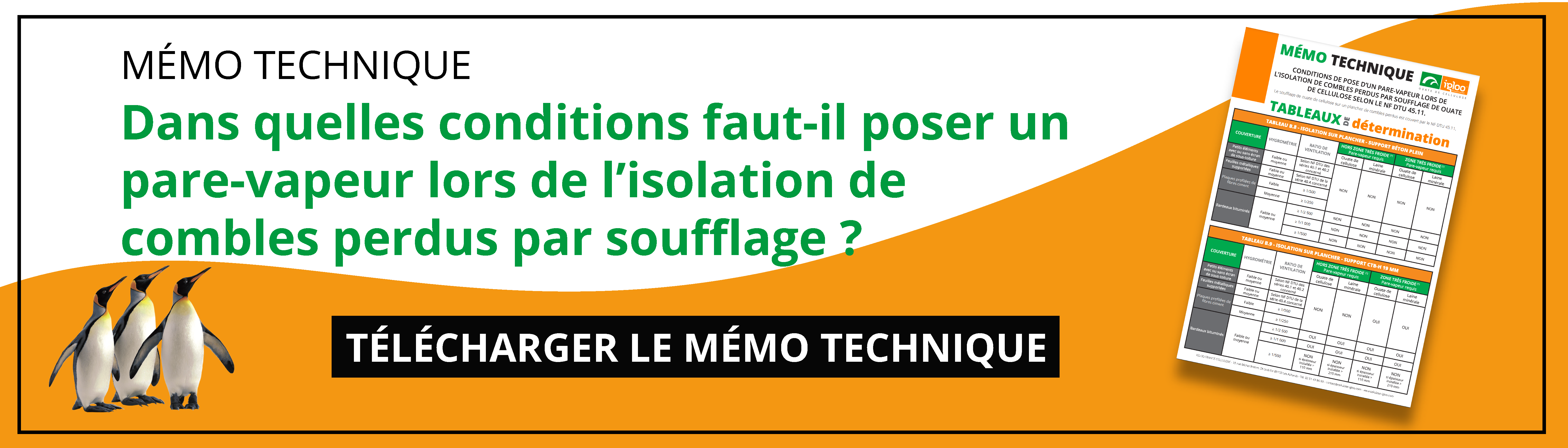

Blown insulation in attics: is a vapor barrier mandatory?

DTU 45.11 stipulates the conditions under which the installation of a waterproofing membrane (or vapor barrier) is mandatory, and those under which it is not. Several criteria are taken into account: the type of substrate (solid concrete, CTB-H, plasterboard), the type of roofing, humidity, the ventilation ratio, and the geographical area.

Par exemple, pour l’isolation des combles par soufflage de ouate de cellulose avec une résistance thermique R = 7m2.K/W, la pose d’un pare-vapeur n’est pas nécessaire sauf dans les cas suivants :

– couverture en bardeaux bituminés (sauf si plancher en béton),

– support non continu comme un lambris en bois,

– zone très froide, définie par une température de base < -15°C.

Blown attic insulation: what training is required?

Training is required to masterblown insulation for attic spaces. This training is quick and can be obtained from training organizations or directly from insulation manufacturers. Generally, one or two days are sufficient to complete training on blown insulation for attic spaces.

Blown attic insulation: what materials should you use?

Toinsulate unused attic space using blown insulation, a machine called a blowing machine. Two operators are required to operate the machine. Thefirst operator stands at the machine and is responsible for feeding it with bags of insulation. Thesecond operator, equipped with a high-frequency remote control, is located in the attic and blows the insulation. This operator controls when to start and stop blowing using the remote control.

The advantage of the carding and blowing machine, as its name suggests, is that it cards the insulation, which has been compacted into bags for transport. This stepaerates the insulation and reforms the flakes.

Then, the same machine will be used to blow the insulation into the unused attic space.

You now know everything there is to know about insulating unused attic space using blown insulation. This is the most common method of insulating attics, due to the immediate benefits it offers: comfort in summer, energy savings, etc. Although it is quick and easy to install, it is nevertheless covered by DTU 45.11 and must be carried out in accordance with best practice. See our dedicated article to find out about the thermal regulations that apply to insulation work.