CELLULOSE INSULATION

THE ULTIMATE BIOSOURCED THERMAL INSULATION

Learn all about cellulose insulation, the ultimate bio-based thermal insulation:

Economical, effective, eco-friendly, and soundproofing.

cellulose insulation a high-performance thermal insulator that combats extreme temperature fluctuations, providing comfort in both summer and winter. Thanks to its technical performance, this bio-based insulation has a significantly higher phase shift than conventional insulation materials. Made from 90% recycled paper fibers, cellulose insulation to attics by blowing and to crawl spaces, walls, and floors by insufflation.

What is cellulose insulation?

A phase shift almost three times greater.

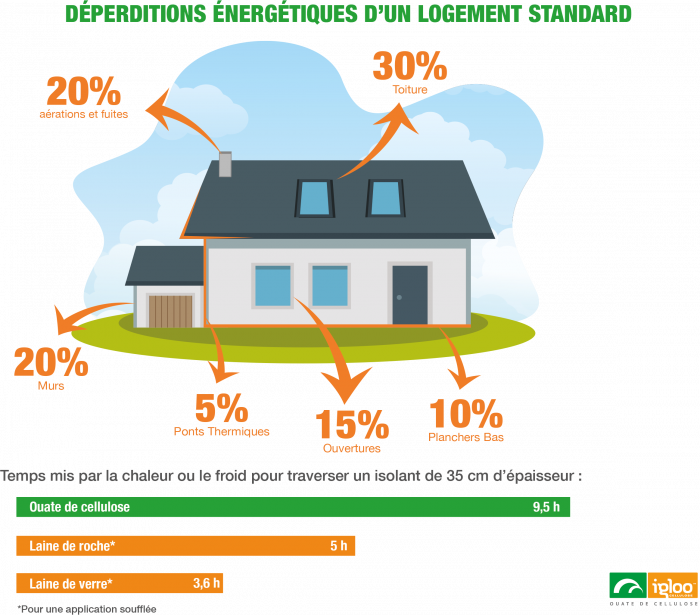

Time taken for heat to pass through blown insulation in lost attic space for an R value of 7 m²/K.W:

An economical insulator.

Every degree gained saves 7% on heating costs!

SAVE ENERGY

Thanks to its exceptional thermal performance, cellulose insulation offers dramatic energy savings compared to mineral insulation. The intertwining of the fibers makes cellulose insulation effective against convection (1). It fills even the smallest gaps and offers high resistance to air flow, guaranteeing a significant reduction in convection within the insulation.

(1) Convection: air circulation due to a temperature contrast, with warm air rising and cold air descending, which can reduce the thermal resistance of insulation by a factor of 4.

COMBAT HEAT LOSS

The attic is where the most heat is lost from a house. The percentage varies from 30 to 35%.

LIFESPAN

Unlike other insulation materials, cellulose insulation has no limited lifespan and does not deteriorate over time. Its longevity is equal to the lifespan of your home, as evidenced by homes that have been insulated for over 40 years in Canada.

High-performance insulation.

Blown or blown-in, cellulose insulation is used for interior insulation. Insulation made with Igloo acts as a shield that reduces the transmission of heat and cold.

AIR BARRIER

cellulose insulation is naturally airtight cellulose insulation the intertwining of its fibers. This thermal insulation blocks any gaps that could allow air to circulate, guaranteeing the elimination of convection in the insulation.

WARM IN WINTER, COOL IN SUMMER

cellulose insulation its density and thermal capacity, cellulose insulation has a phase shift time(2) up to three times higher than that of blown mineral insulation, providing thermal comfort in summer and reduced energy consumption in winter.

(2) Phase shift: the time it takes for heat or cold to pass through the thickness of insulation.

ELIMINATE THERMAL BRIDGES

Blown-in installation allows cellulose insulation fill all cavities, including those that are inaccessible to roll insulation.

DID YOU KNOW?

The University of Colorado compared two identical houses, one insulated with cellulose insulation the other with glass wool.

The test shows that cellulose insulation energy savings of 26.4% compared to glass wool.

In concrete terms, the house insulated with cellulose insulation to be 4°C warmer after a period of 9 hours without heating.

A GESTURE FOR THE PLANET

RECYCLING ONE TON OF PAPER SAVES:

- 3 cubic meters of waste

- 4,000 kWh of energy

- 29,000 liters of water

- 30 kg of CO2

An eco-friendly insulator.

GREEN SOLUTION

Consuming up to 12 times less energy to manufacture than conventional insulation, cellulose insulation made from recycled paper. IGLOO is a "green" solution for your family.

Insulating your home with cellulose insulation , an eco-friendly insulation product, will allow you to spend less on heating and cooling.

Canadian statistics (figures for Canada):

The Cellulose Insulation Manufacturers Association (CIMA) states that insulating a 150 m² house with cellulose insulation as much paper as one person uses in 40 years. If all new homes or renovations were insulated with cellulose, it would remove 3.2 million tons of wasted paper each year.

Acoustic insulation.

SOUND INSULATION SOLUTION

cellulose insulation is a natural barrier to sound propagation.

Since airborne noise is mainly carried through the air, the exceptional interlocking of the cellulose fibers greatly reduces it.

cellulose insulation an end of life?

THOUSANDS OF WELL-INSULATED HOMES FOR OVER 40 YEARS IN CANADA

Generally speaking, and based on feedback from our Canadian friends, cellulose insulation unlimited longevity and does not deteriorate over time. In Canada and Great Britain, surveys carried out in homes dating from 1920 that contain cellulose insulation attest cellulose insulation .

QUALITY INSTALLATION GUARANTEES EFFECTIVE INSULATION

The longevity of cellulose insulation also cellulose insulation largely on several important factors. First, "the quality of attic insulation is directly related to the density of installation. The minimum density for blowing is 24 kg/m3 and 48 kg/m3 for insufflation," explains Charles KIRIE, President of IGLOO FRANCE CELLULOSE. "The quality of the installation is a key factor in ensuring its longevity. For this reason, we do not sell directly to the general public, but only to selected and certified professionals." Properly installed cellulose insulation is therefore a guarantee of efficient insulation. "Because safety is our priority," says Mr. Kirié, cellulose insulation is installed by professionals trained by the company. Applicators are trained in various installation techniques (blowing, insufflation, or flocking).

A network of 80 applicators throughout France meets the demand from the general public for the installation of insulation in their homes.

HUMIDITY CONTROL

Like all bio-based materials, and unlike mineral fibers, cellulose insulation humidity thanks to its hygroscopic fibers: it absorbs excess moisture, stores it, and releases it when the atmosphere becomes drier. Thanks to its long fibers and loose-fill application, cellulose insulation ideal for filling even the smallest gaps and preventing thermal bridges in the insulation. By regulating humidity, cellulose insulation also cellulose insulation the growth of fungi, bacteria, and mold. Thanks to its densely intertwined fibers, cellulose insulation highly unfavorable to rodents settling in the insulation.

WATERPROOFING ALSO WORKS ON A WOODEN HOUSE

WOODEN HOUSE AND cellulose insulation WHEN NATURAL MATERIALS COME TOGETHER

A natural insulator made from cellulose fibers in a wooden house—what could be better? Wood is a natural insulator known for its high thermal and acoustic performance. Like cellulose insulation, wooden houses have many ecological benefits. Wooden houses are dry, clean constructions that do not require water. Wood is alive, it breathes, and it helps us breathe. The combination ofcellulose insulation the ideal combo for meeting RE2020 requirements.

Wooden houses are therefore a good solution to combat the greenhouse effect. The insulation is made from 90% recycled paper. It requires up to 12 times less energy to manufacture than conventional insulation materials. In other words, cellulose insulation wooden houses are a winning combination.

Thanks to its high phase shift, cellulose insulation heat out in summer and in during winter.

QUICK SETUP, EVERYONE IS IN THE GAME!

While it takes more than a year to build a traditional concrete house, it takes no more than six months to build a wooden house. This is because a traditional house requires drying time, which means waiting for the finishes to be completed. In contrast, building a wooden house is a "dry" construction method that avoids this type of waiting time.

The speed with which cellulose insulation can be installed, whether in walls or attics, is ideal for meeting tight deadlines. In general, 50% of a wooden house is manufactured in advance in a production workshop. When the wooden frame components arrive on site by truck, they are already insulated and all that remains is to assemble them.

An IGLOO FRANCE CELLULOSE-approved installer arrives with their equipment (Krendl carding and blowing machine) and blows or sprays the cellulose insulation the walls of the timber-framed house. For a 100 m² house, installing cellulose insulation takes cellulose insulation one to two days on average.

TO GO FURTHER.

Applications.

cellulose insulation a versatile insulation material suitable for insulating attics, walls, and floors, both in new construction and renovation projects.

Implementation.

Available in bulk, cellulose insulation blown into attics, injected into crawl spaces, roofs, and floors, and sprayed wet onto walls.

Request a quote.

Are you a professional and would like to receive a quote for the supply of cellulose insulation France cellulose insulation ?

Find an applicator.

Are you a private individual and would like to be put in touch with one of our certified partners?