MANUFACTURING OF cellulose insulation

Discover how recycled paper is reused in the cellulose insulation manufacturing cycle.

A bio-based, economical, and eco-friendly insulation made from 89% recycled paper, cellulose insulation active cellulose insulation in the circular economy.

STEP 1: COLLECTION

In order to manufacture our cellulose insulation, we collect unsold and/or unused paper locally from French recycling companies. By transforming this waste into eco-friendly, bio-based thermal insulation, we are able to recycle nearly 20,000 tons of it each year.

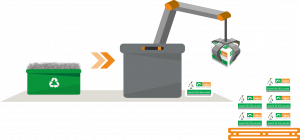

STEP 2: QUALITY CONTROL OF THE COLLECTED PAPER

The quality of the raw material guarantees the quality of our cellulose insulation. We therefore inspect and sort it before processing, retaining only paper that fully complies with our specifications. It must not contain any strapping or plastic, grease, or solvents, and must be dry so that it can be recycled into eco-friendly insulation.

STEP 3: GRINDING

The sorted paper then passes through a knife shredder to calibrate it to a standardized size. It then passes through a magnetic screen to remove any unwanted metal waste.

STEP 4: IMPROVING FIRE-RETARDANT PROPERTIES

A mineral salt-based fire retardant solution is added to enhance the insulation's fire resistance. We conduct daily tests on the material produced to ensure that it complies with current standards and regulations.

STEP 5: DEFIBRILLATION

The paper is then shredded into cellulose insulation an attrition mill. It is thanks to this step that the insulation takes on the form we know today. cellulose insulation composed of paper flakes, allowing it to fill even the smallest gaps. Thanks to its densely intertwined fibers, cellulose insulation naturally heat-resistant, taking up to 2.5 times longer to pass through than blown mineral wool.

STEP 6: QUALITY CONTROL

Before being packaged, our cellulose insulation inspected to ensure that it meets regulatory requirements. These rigorous inspections enable us to guarantee a high-quality, eco-friendly, bio-based insulation product. With over a century of experience, cellulose insulation recognized for its particularly durable performance.

STEP 7: PACKAGING

cellulose insulation compacted into bags for storage and transport to our applicators. It is then applied in the construction of residential and commercial buildings, as well as in renovations, in attics, crawl spaces, walls, and floors. cellulose insulation be blown, injected, or wet sprayed depending on the requirements.

Applications.

cellulose insulation a versatile insulation material suitable for insulating attics, walls, and floors, both in new construction and renovation projects.

Implementation.

Available in bulk, cellulose insulation blown into attics, injected into crawl spaces, roofs, and floors, and sprayed wet onto walls.

cellulose insulation Igloo France Cellulose is certified.

Request a quote.

Are you a professional and would like to receive a quote for one or more of our products?

Find an applicator.

Would you like to be put in touch with an Igloo France certified professional in your area?