CELLULOSE INSULATION

ACOUSTIC INSULATION

In addition to being an excellent thermal insulator,

cellulose insulation also used as acoustic (or sound) insulation.

Why choose cellulose insulation insulate walls, partitions, floors, attics, or ceilings over glass wool or rock wool, among other materials?

We tell you everything you need to know about this interesting acoustic insulation material.

DEFINITION AND TYPES OF NOISE

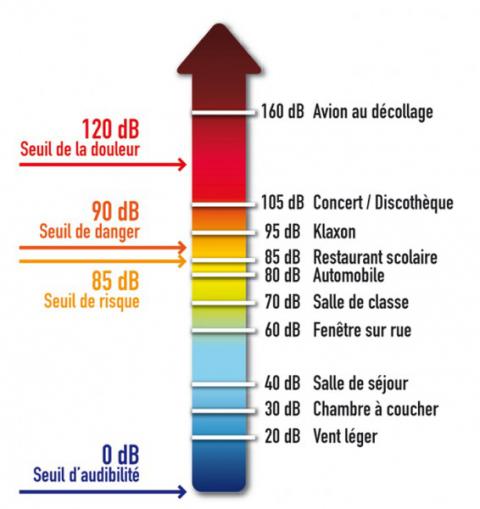

Noise or sound consists of vibrations in the air and is measured in decibels (dB). Decibels measure the level of sound pressure.

It is important to know that there are four types of noise:

– external airborne noise (e.g., road traffic),

– internal airborne noise (e.g., voices)

– impact noises (example: the impact of an object),

– equipment noise (e.g., the operation of an elevator).

Noise intensity is measured on a scale from 10 to 150 dB. An environment is considered quiet below 40 dB, while pain begins to be felt at 120 dB.

Noise levels are not cumulative. Instead, they follow a logarithmic scale: a doubling of the noise level results in an increase of 3dB.

The purpose of acoustic (or sound) insulation in construction or renovation is to prevent everyday noise pollution. This is why absorbent or damping insulation materials are used to separate the partition or floor to be insulated by means of double glazing.

Note: there must be no rigid contact between the insulation and the wall.

ACOUSTIC TREATMENT SOLUTIONS

For acoustic insulation, the best-known insulating materials are, of course, various types of wool: glass wool, rock wool, sheep's wool, hemp wool, or recycled polyester fiber..

The aim is to adhere to a mass/spring/mass principle in order to separate the air gap from the mineral absorbent using a spring and, in this way, toattreduce sound energy at the outlet.

Another option is to use cellulose insulation is made from recycled paper and has become a particularly popular choice for acoustic and thermal insulation.

WHY USE cellulose insulation ACOUSTIC INSULATION?

It was in the 1920s that cellulose insulation gained recognition in North Americato meet the particularly harsh climatic conditions of Canada and the northernmost states of the United States.

In terms of thermal performance, cellulose insulation excellentto(it takes about ten hours for heat to pass through the thickness of theinsulation).

But it is mainly in terms of sound insulation that cellulose insulation interesting. Indeed, due to its density and high resistance to airflow, cellulose insulation a highly effective acoustic insulator.

In attics, cellulose insulation a highly effective acoustic (or soundproofing) insulator against external noise.

When sprayed wet into the walls of a home or commercial building, cellulose insulation additional acoustic comfort for occupants because its cohesion with the substrate and its density greatly reduce the transmission of airborne noise.

Particularly popular in eco-friendly construction and/or wood-frame buildings, cellulose insulation an ecologicalinsulation that can be used toinsulate attics, crawl spaces, walls, and floors. cellulose insulation France cellulose insulation is also dust-free to improve the comfort of the installer. It is also a non-allergenic and non-irritating product.

Request a quote.

Are you a professional and would like to receive a quote for one of our products?

Find an applicator.

Are you a private individual and would like to be put in touch with one of our certified partners?