cellulose insulation,

HIGH-PERFORMANCE INSULATION

The thermal performance of an insulator is measured by its thermal conductivity (lambda), its density, and its phase shift.

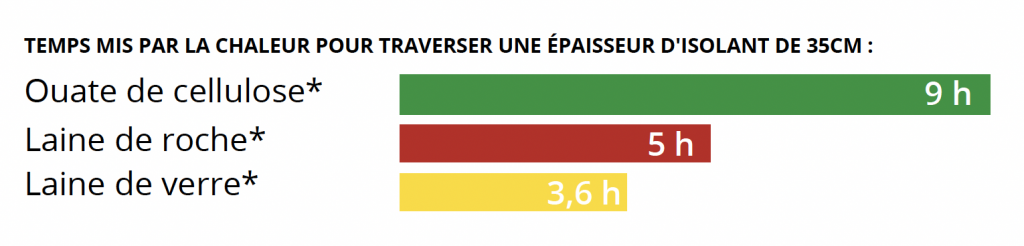

RE2020 AND SUMMER COMFORT

With summers getting hotter and hotter, heat insulation in homes is an important consumer demand, which has been taken into account in the new RE2020 regulations. The thermal performance of cellulose insulation real comfort in summer, when outdoor temperatures are at their highest. It helps to keep the inside of a house cool for around 9 hours with a 35 cm thickness, whereas other insulation materials only resist the outside heat for 3 or 4 hours. The indoor temperature is therefore less sensitive to peaks in the outdoor temperature.

SLOWING DOWN CALORIE TRANSFER

In summer, the sun's rays strike the roof of a building directly, which can then reach temperatures above 50°C. It is therefore essential that its insulation slows down heat transfer for as long as possible, to allow the building to be ventilated when outside temperatures are cooler. Slate and tile roofs combined with plasterboard ceilings have low thermal inertia, so the insulation blown into the attic must provide a high phase shift to ensure comfort in both winter and summer.

ACHIEVE ENERGY SAVINGS

Thanks to its high phase shift, cellulose insulation energy all year round. In winter, the insulation layer retains heat longer, reducing the need for heating systems. In summer, air conditioning systems are also used less.

THERMAL PERFORMANCE CRITERIA

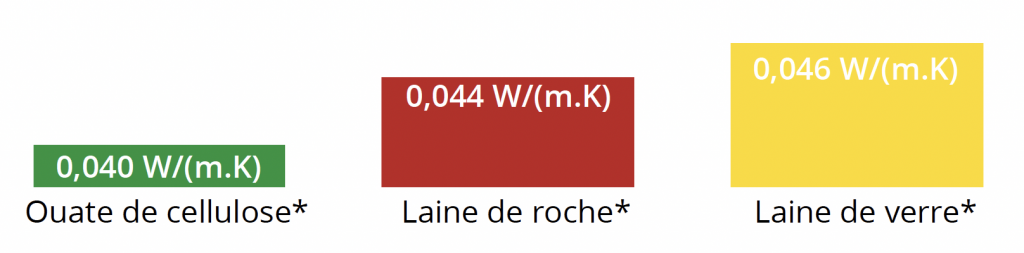

THERMAL CONDUCTIVITY

The thermal conductivity of a material, denoted by lambda, is its inherent ability to conduct heat. The lower the conductivity (small lambda), the greater the insulating power of the material.

*For a blown-on application

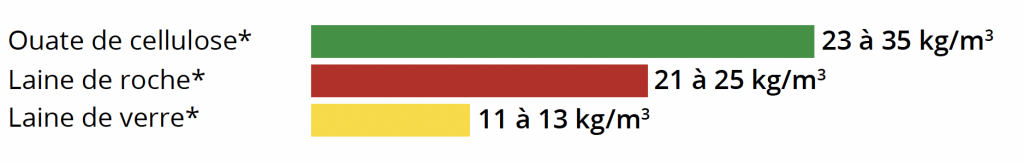

DENSITY

Density represents the weight of one cubic meter of insulation. It is a parameter that is taken into account when calculating phase shift, i.e., a material's capacity to store heat: high density therefore contributes to better thermal performance of the insulation, both in summer and winter.

*For a blown-on application

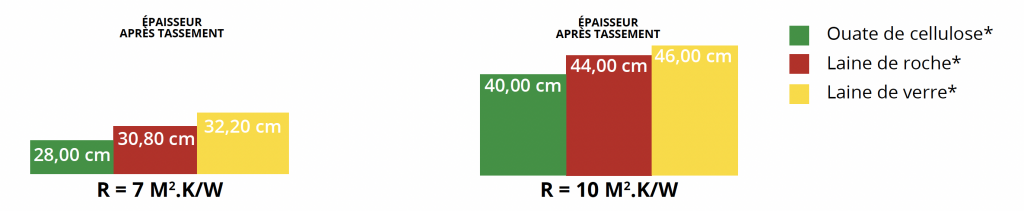

THERMAL RESISTANCE

Thermal resistance, denoted by R, is the ability of a material to resist heat flow. It depends on the thermal conductivity (lambda) and the thickness of the material. The higher the thermal resistance R, the more insulating the material is. To compare the performance of different insulating materials in terms of their thermal resistance, it is necessary to compare the thickness of the insulation required to achieve a defined thermal resistance R.

*Sources: ACERMI certifications Isover & Rockwool

THE PHASE SHIFT

The phase shift is the time it takes for heat to pass through the insulation. The higher the phase shift, the longer it will take for heat to pass through the insulation.

*For a blown-on application

Thanks to its lower thermal conductivity, higher density, and more effective phase shift than mineral wool, cellulose insulation a considerable impact on summer comfort, limiting summer overheating and providing comfort to building occupants.

OTHER STRENGTHS OF cellulose insulation

cellulose insulation other advantages that allow for greater thermal comfort inside the building.

The hygrothermal performance of cellulose insulation

Like a sponge, hygroscopic properties refer to a material's ability to absorb excess moisture, store it, and release it when the atmosphere becomes drier, without altering its thermal performance.

This natural regulation phenomenon limits water vapor condensation and its negative effects, such as mold growth. Air with controlled humidity (between 30% and 60% humidity) also requires less heating. This results in greater comfort.

cellulose insulation hygroscopic, meaning it can absorb moisture up to 15% of its weight and release it when the atmosphere becomes drier. It is a very good hygroscopic regulator and a breathable material.

With a mu of 2, cellulose insulation also open to water vapor diffusion and contributes to creating a healthy hygrothermal climate for building occupants.

Fire behavior of cellulose insulation

The density of cellulose insulation the addition of fire-retardant mineral salts enable it to achieve a good fire rating. In the event of a fire, it will carbonize on the surface, slowing down the spread of flames.

cellulose insulation, due to its densely intertwined structure of recycled paper fibers, slows down the circulation of air in and around its fibers. As a result, the fire retardant treatment incorporated into these fibers, as well as the texture of the product at the end of the manufacturing process, give cellulose insulation excellent fire cellulose insulation .

Because air circulates with difficulty in cellulose insulation fire spreads with difficulty in the insulation. cellulose insulation on the surface and literally slows down the spread of fire.

WEIGHT AND HEAT RESISTANCE

cellulose insulation be blown to a thermal resistance of R=12m2.K/W in unused attic space on a plasterboard ceiling screwed onto furring strips spaced 60 cm apart and fixed to the joists by hangers spaced 1.20 m apart.

Tests on the mechanical behavior of a ceiling under distributed load were carried out by ECIMA and showed a maximum deformation of less than 5 mm with an insulation mass of 16 kg/m².

Blowing cellulose insulation a ceiling to achieve a thermal resistance of 12 m²·K/W in unused attic space is therefore approved.

|

Thermal resistance (m2.K/W)

|

6

|

7

|

8

|

9

|

10

|

11

|

12

|

|---|---|---|---|---|---|---|---|

|

Blown thickness (mm) |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Load per suspension line (DaN) |

28 |

29 |

30 |

31 |

32 |

33 |

34 |

Two NF-tested plasterboard references, CERIB reports no. 012932 and no. 012933 dated November 20, 2018.

The suspension line and sling combination must have a breaking load at least three times greater than the working load of the suspension line indicated in the table, as validated by laboratory testing.

BEHAVIOR IN VENTILATED ATTICS

The weight of cellulose insulation gives cellulose insulation excellent stability in attics. The necessary ventilation, even in stormy conditions, does not affect its thickness and therefore its performance.

The settling phenomenon is taken into account in the performance certified by ACERMI. It is determined by standardized tests as part of the product certification process. Thus, the certified thermal resistance of cellulose insulation is given for a minimum insulation thickness to be installed, which corresponds to a minimum thickness after settling.

Thanks to its characteristics, cellulose insulation an attractive thermal insulator for interior insulation in buildings. Its excellent thermal performance meets the new summer comfort requirements set by RE2020 and enables energy savings throughout the year. Other qualities set it apart from conventional insulation materials, such as its reaction to fire, its hygroscopic performance, its behavior in attics, its carbon footprint, and its longevity. For over 100 years, it has been used in countries accustomed to extreme temperature variations, such as Canada and Finland, where one in two homes is insulated with cellulose insulation.

Request an appointment.

Are you a professional and would like to meet with one of our sales representatives to learn more?

Find an applicator.

Are you a private individual and would like to be put in touch with one of our certified partners?