Bio-based insulation materials are gaining popularity due to their renewable nature and low environmental impact. Several materials are available, each with its own specific characteristics and applications. Here is an overview of the best bio-based insulation materials, along with their respective strengths and weaknesses.

Hemp wool

Hemp wool is one of the most widely used bio-based insulation materials. Made from hemp fibers, this wool offers excellent thermal and acoustic insulation properties. It is often used in wall and floor insulation. Hemp wool is moisture-resistant and naturally regulates ambient humidity.

Made from the fibers of the hemp plant, this wool offers a sustainable alternative to traditional insulation materials. In terms of thermal performance, hemp wool offers excellent results, helping to maintain a comfortable indoor temperature while reducing energy costs. Its fibrous structure creates pockets of trapped air, providing effective insulation against heat in summer and cold in winter.

Like most bio-based materials, hemp wool offers advantages in terms of moisture regulation. It has the ability to absorb and release moisture as needed, helping to prevent condensation and moisture problems in building structures. This hygroscopic capacity contributes to the material's durability while improving indoor comfort.

Hemp wool has a variety of applications in building insulation. It is often used to insulate walls, partitions, and floors. In panel form, its flexibility allows for quick and easy installation. In addition, it can be used in combination with other insulation materials or as the primary material, offering great versatility in construction and renovation projects.

In addition to its insulating properties, hemp wool is an environmentally friendly choice due to the sustainability of the hemp plant itself. Grown without the need for intensive pesticide use and capable of growing in a variety of conditions, hemp is a renewable resource. Furthermore, the manufacture of hemp wool generally requires less energy than that of synthetic insulation, thereby helping to reduce the material's carbon footprint.

Wood fiber

Wood fiber is used in various forms of insulation, such as rigid panels, semi-rigid panels, and loose fill. Wood fiber panels are commonly used for insulating walls (ITI/ITE), roofs, and floors. Loose fill is mainly used for insulating attics. Wood fiber offers excellent thermal and acoustic properties, as well as the ability to regulate humidity.

Produced from wood fibers, often from conifers such as pine or spruce, wood fiber combines effective insulating properties with significant environmental benefits. Its long, flexible fibers create an airy structure that traps air, ensuring optimal thermal insulation.

This bio-based material stands out for its versatility and ease of installation. Wood fiber is available in various forms, including rigid panels, semi-rigid panels, and loose fill. This variety allows it to be used in different contexts, from walls to roofs, floors, and attics. Rigid panels are often used for exterior wall insulation, while semi-rigid panels are well suited for use in interior walls and roof slopes.

Like most bio-based materials, it also has hygroscopic properties that enable it to regulate humidity. It can absorb and release moisture depending on ambient conditions, thereby helping to maintain thermal comfort inside the building.

cellulose insulation

Cellulose cellulose insulation is made from recycled paper fibers, mainly from waste from the paper industry. It is mainly used in bulk form to insulate attics, walls, and floors. It is also available in panel form, mixed with other natural fibers. cellulose insulation high thermal and acoustic performance. It also stands out for its ability to regulate humidity thanks to its hygroscopic properties.

Particularly popular for insulating unused attic space, cellulose insulation the most widely used bio-based insulation material (20% market share). It significantly improves the energy efficiency of buildings, whether blown into unused attic space or injected into closed cavities (e.g., wood-frame walls). In addition to its thermal properties, cellulose insulation also cellulose insulation at absorbing noise, making it an ideal choice for acoustic insulation in buildings.

In countries with extreme temperature variations, such as Finland and Canada, cellulose insulation the most widely used thermal insulation material. Its ability to maintain effective thermal insulation, even in extreme climatic conditions, makes it a preferred choice for responding to climate change in France in recent years.

In addition to its insulating properties, cellulose insulation recognized for its low environmental impact. Its manufacturing process uses recycled materials from natural resources (wood), thereby contributing to waste reduction. Furthermore, cellulose insulation the properties of wood and stores biogenic carbon (CO2) throughout its lifetime.

Cork

Expanded cork is a plant-based insulation material obtained from the bark of the cork oak tree. It is lightweight, durable, and offers excellent thermal performance. Expanded cork is often used in wall, floor, and roof insulation. It is valued for its low environmental impact and resistance to moisture.

Cork is one of the best bio-based insulators due to its unique properties, including its durability and exceptional thermal performance. Cork is obtained from the bark of the cork oak tree, a sustainable harvesting process that allows the tree to regenerate its bark. This renewable characteristic helps reduce cork's carbon footprint.

It stands out thanks to its water impermeability and durability. Due to a natural substance called suberin present in its bark, cork is virtually impermeable to water, thus protecting it from rot, decomposition, and deterioration due to moisture. This characteristic makes cork an ideal insulator for environments subject to climatic variations and fluctuating humidity levels.

In addition to its water resistance, cork offers excellent thermal performance. It has low thermal conductivity, which means it is able to effectively slow down heat transfer.

Cork comes in various forms, including expanded cork panels, cork granules, and agglomerated cork sheets. These variations allow for versatile use of cork in wall, floor, and roof insulation. Expanded cork panels, for example, are frequently used for exterior wall insulation, while cork granules can be used in bulk for insulating attic spaces.

The main obstacle to using cork for insulation is often its higher cost compared to other insulation materials. Although cork offers exceptional thermal performance and sustainable properties, its price can be a financial barrier for some projects. However, it is important to consider this investment as a long-term contribution to the building's energy efficiency and environmental sustainability, which can translate into significant savings on heating and cooling costs in the long term.

Recycled cotton/textiles

Recycled cotton and/or textiles are also excellent bio-based insulators, combining ecological characteristics with remarkable thermal and safety performance. Obtained from recycled textile fibers, this material promotes the reuse of existing resources. Recycled cotton stands out for its reaction to fire. Not only is it non-flammable, but it is also self-extinguishing, offering increased protection against fire hazards.

The versatility of recycled cotton is evident in its various forms, which are suitable for a wide range of interior applications. In the form of semi-rigid panels and rolls, recycled cotton or textiles are ideal for insulating walls, floors, and ceilings. Also available in bulk, recycled cotton is an effective option for insulating attics. These various configurations allow recycled cotton to be adapted to the specific needs of each construction or renovation project.

In addition to its insulating properties, recycled cotton offers significant acoustic benefits, helping to reduce noise and improve sound comfort inside buildings. Furthermore, its hypoallergenic nature makes it a safe choice for indoor environments, reducing allergy-related risks.

Recycled cotton is therefore a leading bio-based insulation material, combining durability, thermal performance, fire safety, and versatility of application. Its use offers an environmentally friendly and responsible alternative, meeting the growing demands for sustainability in the field of building insulation.

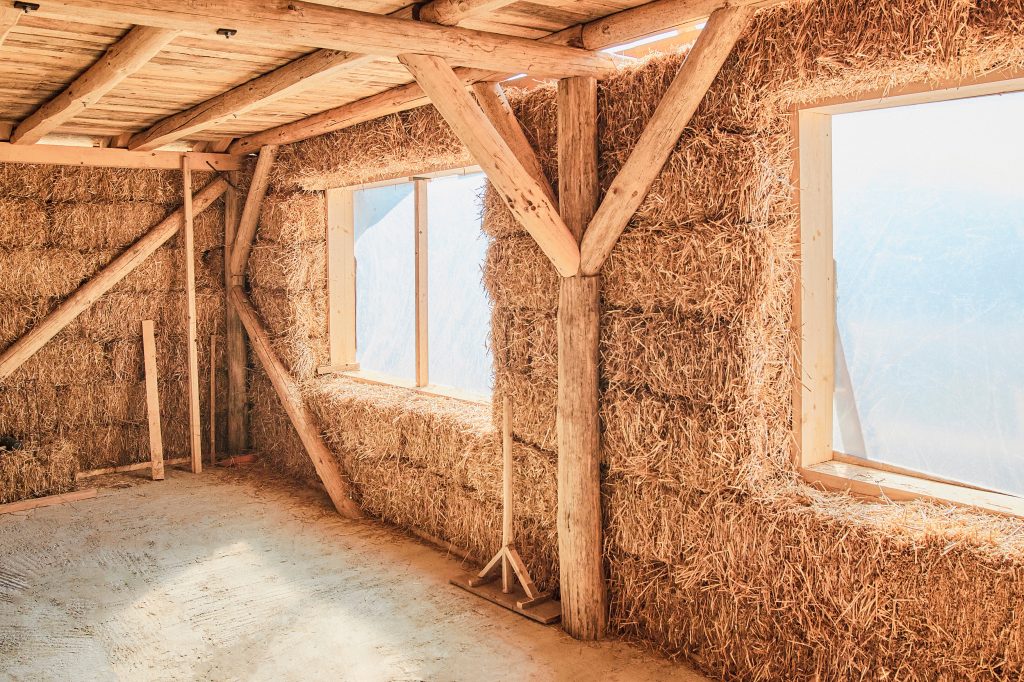

Straw

Straw derives its advantages from its plant-based, renewable, and abundant nature. Consisting mainly of cereal stalks such as wheat, barley, or rye, straw is a renewable agricultural resource, offering an environmentally friendly alternative to conventional insulation materials. Straw is often used in two main forms: straw bales and chopped straw.

Straw bales, compressed and bound, are an option for structural insulation. They can be used as a building material in their own right, forming the load-bearing walls of buildings. Chopped straw, on the other hand, is more often used in bulk for insulation applications, whether to fill walls, floors, or attics.

The versatility of straw extends to its use for both interior and exterior insulation in buildings. Indoors, straw can be used in partitions and linings to improve the thermal and acoustic performance of spaces. Outside, it can be used as filler insulation in wood-frame walls, for example, while ensuring continuous and uniform insulation.

Straw offers remarkable insulating properties due to its low thermal conductivity and ability to regulate humidity. It creates an effective thermal barrier, helping to maintain comfortable indoor temperatures throughout the year. In addition, straw contributes to the reduction of greenhouse gas emissions, as it stores carbon during crop growth and retains this property throughout the life of the insulation.

Straw is positioned as a bio-based insulation material of choice, offering an eco-friendly and sustainable alternative for insulating buildings. Its versatility, local availability, and thermal performance make it an attractive option for those seeking environmentally friendly solutions in the construction industry.

The various bio-based labels for the building industry

Several labels certify the bio-based content in construction or in the materials themselves.

"Bio-based Building" label

The "Bio-based Building" state label promotes the use of bio-based materials in construction. It defines a regulatory framework that is voluntary in nature.

Certification:

The "bio-based building" label is only awarded to buildings that have been certified for their overall quality, particularly their energy performance and the suitability of the products used in their construction.

The certifying bodies that can issue the bio-based building label in conjunction with their certifications are: CERQUAL (Qualitel Association); CEQUAMI (Qualitel Association) and CERTIVEA.

"Bio-based product" label

The "Bio-based Product" label aims to improve the visibility and recognition of construction products containing a significant percentage of bio-based raw materials.

It is a private label, established by theKARIBATI cooperative.

The European terminology standard NF-EN 16575 defines a bio-based product as being "wholly or partly derived from bioresources."

The "Bio-based Product" label was therefore created to distinguish bio-based materials containing a significant proportion of biomass, by certifying their bio-based raw material content. A minimum threshold for bio-based material content is set for each product family, based on what's currently available on the market (for example, it's set at 70% for insulation and 25% for plant-based concrete).

A new label, "Produit Biosourcé Plus" (Bio-based Plus Product), was introduced in 2021 to highlight certified bio-based products with a bio-based content of over 80%.

"Bio-based product +" label

This new label, "Produit Biosourcé Plus" (Bio-based Plus Product), was introduced in 2021 to highlight certified bio-based products with a bio-based content of over 80%.

For more information about this label, visit:Biosourced Label

The choice of the best bio-based insulation therefore depends on a multitude of criteria: intended use, installation, budget, expected characteristics, various constraints, etc. In fact, there is no such thing as the best bio-based insulation per se. Each material has its strengths and weaknesses, and only thorough technical consideration will enable them to be optimized to take advantage of each one, depending on each construction or renovation project. It is also important not to confuse the concepts of bio-based, eco-sourced, geo-sourced, and biodegradable.