CHOOSING cellulose insulation RE2020 CONSTRUCTION

Used for over 100 years, cellulose insulation more and more market share in the attic insulation sector in France (around 20% in 2020).

What's more, this insulation material perfectly meets the requirements of the new RE2020 environmental regulations.

We tell you everything you need to know about using cellulose insulation RE2020 construction.

CONTEXT AND HISTORY OF THE REGULATION

Applicable since 2022 for all buildings, the RE2020 standard replaces the RT2012 thermal regulation. Therefore, if you are planning to construct a commercial building or a single-family home, you must take new criteria into account.

Introduced in 2005, thermal regulations have evolved significantly over the years. In 2007, the BBC label came into effect, and thermal regulations were updated in 2012 with RT2012.

Since 2007, there has been talk of low-energy buildings (BBC). With the RE2020 standard, the aim is to get as close as possible to energy neutrality. This involves both choosing the right materials and working on energy losses from both the outside and the inside.

WHAT CHANGES WITH RE2020

Today responsible for 44% of energy consumption in France and nearly 25% of CO2 emissions, the building sector is a key issue in the fight against global warming.

The new 2020 environmental regulations (RE2020) further encourage the bioclimatic design of new buildings in order to achieve the targets set by the Grenelle Environment Forum for reducing greenhouse gas (GHG) emissions by 2050.

To achieve this, RE2020 strengthens these requirements in terms of energy performance and comfort in buildings, while reducing their carbon impact by setting three new objectives:

- reduce the carbon impact of the building sector by 49% by 2023,

- reduce the energy consumption of buildings by 30%,

- ensure comfort in summer.

RE2020: MEASURING ENVIRONMENTAL IMPACT

To enable the environmental impact of a RE2020 building to be measured, it introduces the calculation of the building's environmental impacts throughout its entire life cycle. This assessment is based on the principle of life cycle assessment (LCA). LCA makes it possible to objectively assess the building's impacts through a series of environmental indicators calculated at all stages of its life cycle.

This development has led to the emergence of two assessment indices: the energy IC index and the construction IC index.

The energy IC index assesses the impact of energy consumption throughout the building's lifetime (50 years). The construction IC index measures the impact of the building materials used in the construction of the building (from the extraction of raw materials to their use on site). It represents the sum of the component IC and site IC indices.

RE2020: MEASURING ENERGY PERFORMANCE

As with RT2012, RE2020 continues to improve energy performance and reduce consumption in new buildings. RE2020 goes beyond the requirements of RT2012, placing particular emphasis on insulation performance regardless of the heating system installed, thanks to stricter requirements on the bioclimatic need indicator, Bbio.

Energy performance measurement indices under RE2020

The Bbio index

The bioclimatic needs indicator (Bbio) represents the energy requirements of a building for heating, cooling, and lighting. Already used in RT2012, its requirements have been strengthened in RE2020 with the systematic consideration of cooling needs (whether or not an air conditioning system is installed, cooling needs will be calculated).

The Cep index

The conventional energy consumption indicator (Cep) measures the energy consumption of heating, cooling, domestic hot water, lighting, ventilation, and auxiliary equipment. With RE2020, additional building uses are added.

The Cep index,nr (new)

The conventional non-renewable energy consumption indicator (Cep,nr) represents the building's primary non-renewable energy consumption for the same uses as the Cep. This indicator therefore only takes into account non-renewable energy sources used to meet the building's needs.

TheICénergie index (new)

TheICénergie indicator represents the impact on climate change of energy consumption during the building's lifetime, i.e., 50 years. This index was created with RE2020 and encourages the use of carbon-free energy sources. It is therefore both an energy and environmental indicator.

RE2020: TAKING SUMMER COMFORT INTO ACCOUNT

In RE2020, summer comfort is defined as a building's ability to maintain a comfortable indoor temperature during hot periods of the year without the use of cooling systems. It therefore depends on several factors, such as building design, choice of construction and insulation materials, building inertia, ventilation, and solar protection.

In this regard, RE2020 proposes several measures to help optimize summer comfort in new buildings.

For example:

- higher thermal performance requirements,

- requirements for sun protection,

- requirements for natural ventilation,

- requirements for thermal inertia.

The choice of low-carbon materials:

a real lever for responding to the new challenges of RE2020.

RE2020 CONSTRUCTION: WHY CHOOSE cellulose insulation

Today, glass wool, rock wool, and hemp wool are widely used materials in construction in France. Not to mention expanded polystyrene, which is highly prized, particularly for exterior insulation.

Cellulose cellulose insulation has been used for over a century in countries accustomed to extreme temperature variations (Canada, Finland, etc.), particularly in wood-frame construction. In France, with the arrival of RE2020, which promotes the use of bio-based materials, the use of cellulose insulation ground over the years. Today, one in five attics is insulated with cellulose insulation, making it the most widely used bio-based material for this application.

This is due to its excellent thermal performance, particularly in terms of summer comfort, its ease of application by blowing, and its benefits in terms ofacoustic insulation.

Easy to apply to roofs (loft spaces and sloping ceilings), walls, and floors, it is also particularly suitable for wooden constructions, where it is blown into the walls (pre-fabricated or on-site).

Combined with wood frame construction, cellulose insulation a winning combination for meeting the challenges of RE2020 construction.

BETTER THERMAL PERFORMANCE

The thermal performance of an insulator is measured by its thermal conductivity (lambda), its density, and its phase shift.

Thermal conductivity: 0.039 to 0.040 W(m.K)

Density: 23 to 35 kg/m³ (blowing)

Thermal resistance R = 7 m²·K/W: 28 cm thick after settling

Thanks to its lower thermal conductivity, higher density, and more effective phase shift than mineral wool, cellulose insulation better thermal performance. It therefore helps to save energy.

Time taken for heat to pass through blown insulation in lost attic space for an R value of 7 m²/K.W:

A PLUS FOR SUMMER COMFORT

With summers becoming increasingly hot, insulating homes against heat is an important consumer demand, which is taken into account in RE2020.

The thermal performance of cellulose insulation real comfort in summer, when outdoor temperatures are at their highest.

It helps to maintain the internal coolness of a house for around 9 hours when blown into the attic space to a thickness of 35 cm, whereas other insulation materials only resist external heat for 3 or 4 hours.

The indoor temperature is therefore less sensitive to outdoor temperature spikes.

Thanks to its thermal performance, cellulose insulation the challenges of summer comfort, a strategic point in RE2020 construction.

A NEGATIVE CARBON FOOTPRINT

Made from mechanically shredded recycled paper, it is interesting to note that cellulose insulation water nor heat during its manufacturing process, making it energy efficient.

In addition, it is of particular interest to professionals who already take the RE2020 standard into account due to its negative carbon footprint.

In addition, cellulose insulation also cellulose insulation 1.37 times its weight in CO2 equivalent throughout its lifetime.

At the end of its life, cellulose insulation in turn be recycled into paper pulp, or back into cellulose insulation.

Thanks to its environmental performance and good carbon footprint, cellulose insulation particularly well suited for the construction of RE2020 buildings.

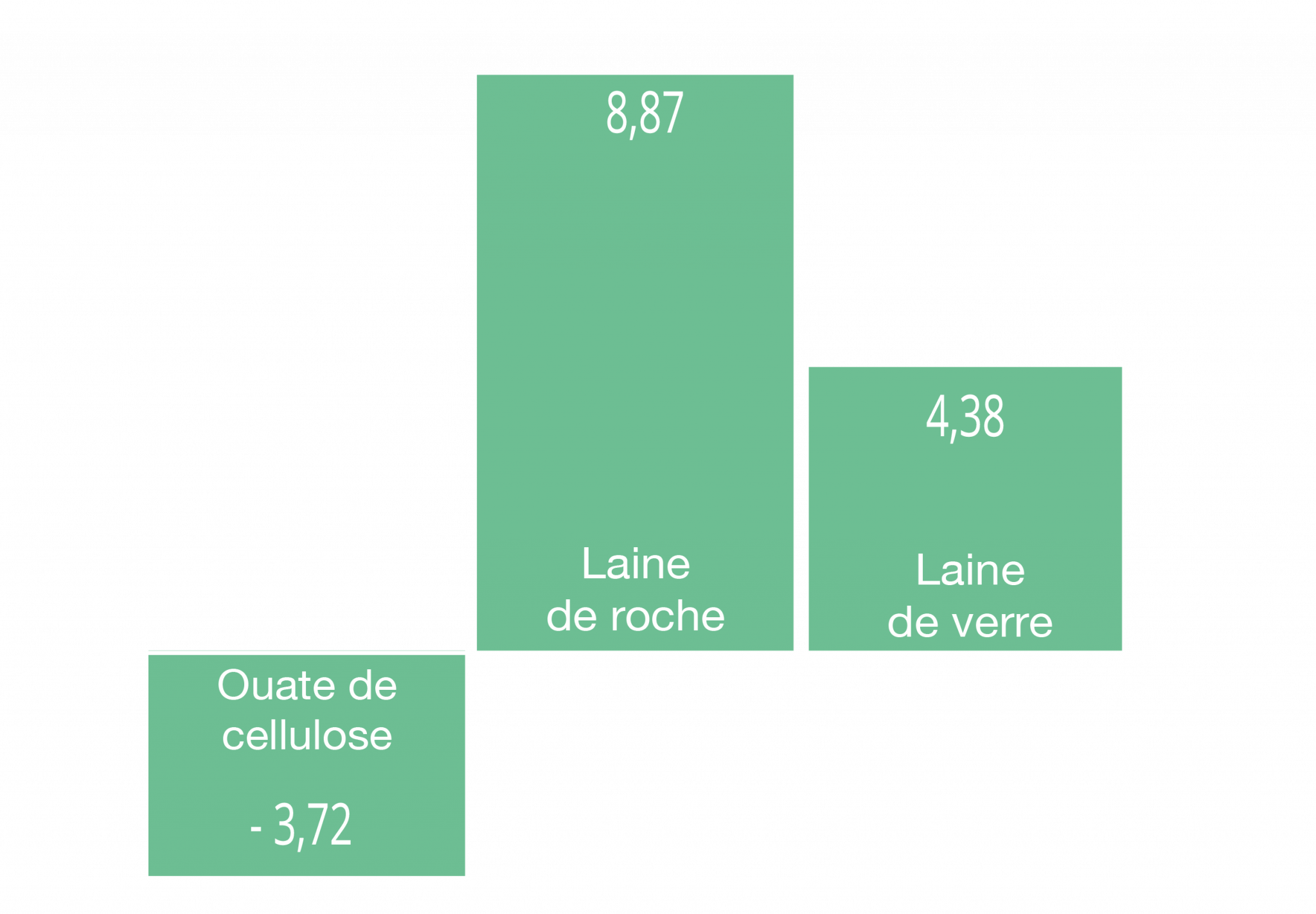

Environmental impact on global warming in kg of CO2 equivalent for blown insulation with a thermal resistance of R = 7 m2/K.W over its entire lifespan (source: FDES verified by Inies).

OTHER STRENGTHS OF cellulose insulation RE2020 CONSTRUCTION

cellulose insulation also cellulose insulation other strengths that make it well suited to meeting the challenges of RE2020 construction:

Its density

Its density and the addition of fire-retardant mineral salts give it good fire resistance. In the event of a fire, the surface will char, slowing down the spread of flames.

Its hygroscopic properties

cellulose insulation hygroscopic, meaning it can absorb moisture (up to 15% of its weight) and release it when the atmosphere becomes drier. With a mu of 2, it is also open to water vapor diffusion and helps create a healthy humidity and temperature climate for building occupants.

His behavior in the attic

The weight of cellulose insulation gives cellulose insulation excellent stability in attics. The necessary ventilation, even in stormy weather, does not affect its thickness and therefore its performance.

A known and measured settlement

cellulose insulation by Igloo France Cellulose is therefore particularly suitable for buildings that wish to meet the specifications of the RE2020 Environmental Regulations.

VERSATILE IMPLEMENTATION

Crawling

by insufflation

Walls

By wet spraying and blowing

Unused attic space

By blowing

Floors

By insufflation

cellulose insulation interior insulation

Beyond its performance, cellulose insulation other advantages thanks to its loose-fill form. This allows it to be used in all interior insulation applications in buildings, both new and renovated. Regardless of the thickness of the cavities to be insulated, it adapts to all configurations, meaning that only one product needs to be kept in stock. cellulose insulation to all constraints, without the need for cutting or product loss.

Request an appointment.

Are you a professional and want to learn more about cellulose insulation

Receive a sample.

Are you a professional and would like to receive a sample of our cellulose insulation