The Low Carbon Prescribers HUB analyzes the bio-based materials sector from the perspective of carbon neutrality. Indeed, in order to achieve the RE2020 carbon storage targets, construction using bio-based materials is becoming inevitable. So, what are the benefits of bio-based materials in terms of carbon-free construction?

Background and challenges

RE2020 is strengthening its carbon neutrality requirements in order to achieve the Low Carbon Neutrality Strategy targets set for 2050.

Bio-based materials are among the range of levers currently available. While they have been promoted in recent years for their benefits in terms of summer comfort, they also have the ability to naturally store carbon.

In 2021, bio-based insulation materials account for around 11% of the market share in France, according to the AICB (Association of Bio-based Construction Manufacturers).

The environmental benefits of bio-based products

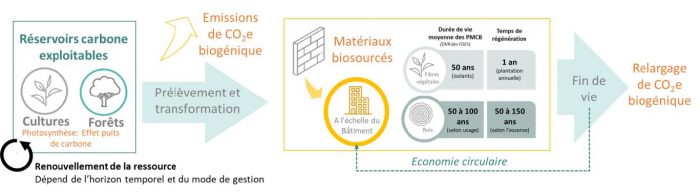

In recent years, bio-based materials, particularly wood, have been promoted for their role in mitigating global warming. To fully understand the carbon benefits of these materials, it is necessary to distinguish between two effects: the sequestration effect and the substitution effect.

The sequestration effect

The sequestration effect represents the biogenic storage incorporated into the product/material. Bio-based materials are mainly derived from plant biomass. Through photosynthesis, this biomass captures and stores biogenic carbon. When it is harvested and transformed into bio-based materials, theCO2 it contains continues to be stored throughout the material's lifetime (between 50 and 100 years on average).

The substitution effect

Bio-based materials are produced using processes that are less energy-intensive and carbon-intensive than conventional construction products. Their use allows for the substitution of energy-intensive materials or fossil fuels. The hub conducted a detailed iso-functional comparison study on a number of materials in the following categories: partitions, cladding, windows, doors, hard floor coverings, wall coverings, flooring, and insulation.

Median performance levels show potential gains for iso-functional products already exceeding SNBC 2030 (-35%) and even 2050 (-81%) levels.

Thus, the most significant benefit of bio-based materials is their substitution effect:

– for most categories of materials, bio-based materials are the lowest carbon categories.

– their carbon performance is, in most cases, aligned with the emission reduction levels required to achieve SNBC targets.

In fact, within a material category, when we compare bio-based materials to other materials in the same category, we see gains of around 60% in carbon savings.

For example (calculations based on median values for conventional products in each category):

– Wood/aluminum windows/French windows: -26% (between 20 and 40kgCO2e/UF)

– Hard flooring/parquet: -44% (between 10 and 15kgCO2e/UF)

– Flooring/wood: -95% (between 80 and 100kgCO2e/UF)

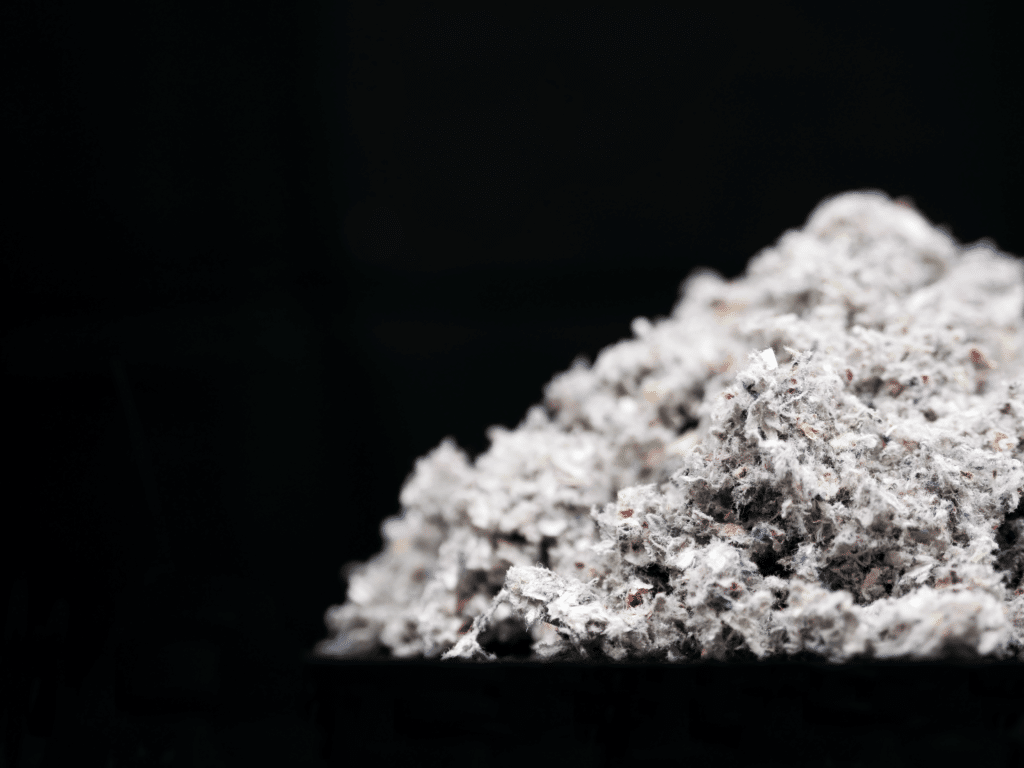

– Bulkcellulose insulation -72% (between 0.5 and 0.7kgCO2e/UF)

*for a thermal resistance of 1m2.K/W.

Does location influence carbon benefits?

In order to quantify the carbon impact of the distance between the production site and the construction site, a study was conducted on insulation materials (wood wool, cellulose insulation, straw, and hemp) and floor coverings (vinyl and non-vinyl PVC, linoleum, marmoleum, solid or engineered wood flooring).

For insulation materials:

A critical distance beyond which the use of bio-based materials becomes counterproductive has been established (in terms of carbon impact compared to conventional materials):

– Wood wool: > 900km

– cellulose insulation straw / hemp: > 3,400 km

This is the distance at which bio-based insulation becomes more carbon-intensive than rock wool (for rock wool produced on average at 460 km – source: FDES).

On a national scale, bio-based materials therefore remain less carbon-intensive than their conventional counterparts, regardless of distance.

With a carbon gain of around 60% for bio-based materials compared to conventional materials in the same category, and a distance at which they become counterproductive exceeding 900 km, the use of bio-based materials is inevitable in carbon-neutral construction. However, these materials present operational challenges that must nevertheless be taken into account in specifications (cost, technical characteristics, availability, insurability).

See the full brief on the bio-based sector by the Low Carbon Prescribers Hub.

Source: Industry brief "Bio-based: key messages" published by the Low-Carbon Prescribers Hub in 2021.